Description

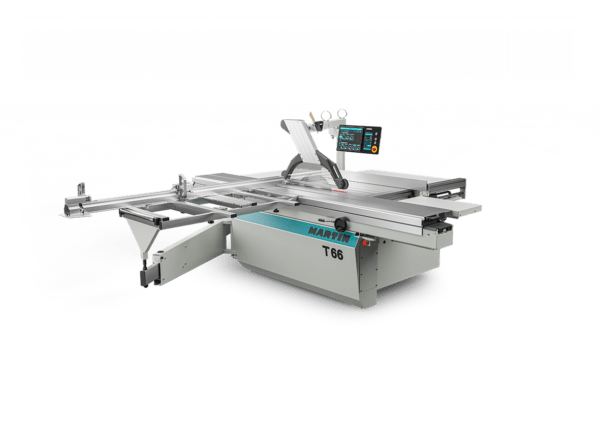

MARTIN Format Circular Saw T66

Technical Data:

Control: 7″ TouchScreen ConnectTouch Control

Saw height & tilt electronically controlled with digital measurement display

Also the movement of the motorized axes in Hold Mode (movement of the axes via push button)

Display reading: 0.1mm – 0.1°, with repeatability accuracy of +/- 0.025 mm and – 0.005°

Weight: 1,200 – 1,700 kg

Table dimensions: 850 mm x 1,100 mm, cast iron

Table extension standard across the full width of the table

Table height: 900 mm

Frame: Double-wall steel-concrete composite frame with very high stiffness and vibration absorption

Cutting width: 850 mm, optionally up to 1350 mm

Saw blade diameter: Standard: 250 – 450 mm

Saw spindle: Ø 30 mm, with 2 pickup holes, pre-cutter Ø 22 mm

Maximum tool width 15 mm

Saw blade change: Quick-change system “ProLock”

Tilt range of the saw: 0° – 46° (with saw blade max. 5 mm)

Cutting height:

0°: max. 155 mm / saw blade Ø 450 mm

45°: max. 110 mm / saw blade Ø 450 mm

Motor: SynchroDrive Type IE4 – Super Premium Efficiency, energy efficiency class, synchronous asynchronous motor

Motor power: 4 kW, optionally up to 7.5 kW, which due to its design can withstand multiple peak loads in a short time, offering a large power reserve above the nominal power

Speed: Steplessly adjustable 1,000 – 6,000 rpm

Control panel: Control field at eye level, rotatable, ergonomic. Includes document holder

Roller table: Standard length 3000 mm, table length equals saw length, lockable at any position, hardened strips, wear-resistant and self-cleaning, replaceable table lips, anodized

Length stop: Anodized aluminum with continuous stop rail, fine adjustment with magnifier for both stop elements

Measurement display on scale. Length correction for

saw length 95 – 2000 mm, extendable up to 3220 mm

Support table: Standard version galvanized, table dimensions 1340 x 650 mm

Dust extraction: Saw guard extraction Ø 80 mm, machine frame Ø 120 mm, minimum 21 m³/min at least 800 Pa underpressure

Accessories: Edge trimmer, retractable handle, push stick, hex keys, 2 riving knives

Electrical section: Lockable main switch, electronic brake; soft starter; motor protection relay, emergency stop, 3~/ 400V – 50 Hz

Emission values:

Noise level according to DIN EN ISO 11202 no load dB 83, loaded dB 84

Peak noise level DIN EN ISO 3746 no load dB 95, loaded dB 95

Dust emission according to DIN 33893 BGI 739, add. 4

Technical execution of the control:

ConnectControl is the overarching term for the control concept of the latest generation of format saws and milling machines from Martin, patented by Martin. With ConnectControl, you get a uniquely designed, highly efficient control concept that not only opens up entirely new horizons for machine operation but also unlocks the entire world of modern data exchange possibilities.

With the 7″ TouchScreen ConnectTouch with high resolution in the modern 16:9 format, all motorized axes of the T14 can be operated comfortably, quickly, and efficiently. The user-friendly interface supports you in all dimension entries, and all displays refer to the tool you have specified.

With the ConnectPad and the ConnectApp running on it, you can always get more electronic support for the machine, even afterwards. This solution provides you not only with electronic support for machine operation but also all the possibilities offered by network and internet connections.

Combined with the ConnectDrive Cloud solution, all forms of data exchange with other software solutions for your production planning are available to you.

Performance levels of machine control

Basic Functions:

| Function | Connect Touch | ConnectApp Classic | ConnectApp Premium |

|---|---|---|---|

| Saw height electronically controlled | ● | ● | ● |

| Saw tilt electronically controlled | ● | ● | ● |

| Saw width electronically controlled | ○ | ○ | ○ |

| Pre-cutter height electronically controlled | ○ | ○ | ○ |

| Pre-cutter position electronically controlled | ○ | ○ | ○ |

| Pre-cutter width electronically controlled | ○ | ○ | ○ |

| Stepless speed control | ● | ● | ● |

| Speed display | ● | ● | ● |

| Saw speed display | ● | ● | ● |

| Axis movement via push button / fine adjustment positioning | ● | ● | ● |

| Repeat button for axis movements | – | ● | ● |

| Automatic correction of saw height when tilting | ● | ● | ● |

| Number of tool management in the library (Online/Offline) | 1 | 999 | 999 |

| Programs / saw lists | – | 999 | 9999 |

| Calculator (with integrated result to the axes) | – | ● | ● |

| Calibration function for controlled axes | ● | ● | ● |

| Hour counter | ● | ● | ● |

| USB interface | ● | ● | ● |

| Machine diagnosis | ● | ● | ● |

| Help pages | – | ● | ● |

Calculation and operation aids

| Function | Connect Touch | ConnectApp Classic | ConnectApp Premium |

|---|---|---|---|

| Workpiece thickness correction | ● | ● | ● |

| Folding | – | ● | ● |

| Groove (single and multiple) | – | ● | ● |

| Incremental measurement | – | ● | ● |

| Angle strip | – | ● | ● |

| Angle cut with oversize | – | ● | ● |

| Photo lists | – | – | ● |

| Dowel and slot work | – | – | ● |

| Geometric shapes (triangle, trapezoid, parallelogram) | – | – | ● |

| Funnel (backrest) | – | – | ● |

| Wrong angle | – | – | ● |

| Shrink and swell measurement | – | – | ● |

Machine expansion via control

| Function | Connect Touch | ConnectApp Classic | ConnectApp Premium |

|---|---|---|---|

| Laser | ○ | ○ | ○ |

| Coolant lubrication | ○ | ○ | ○ |

Protection cover monitoring

| Function | Connect Touch | ConnectApp Classic | ConnectApp Premium |

|---|---|---|---|

| Collision monitoring saw blade tilting (1×45) | – | – | – |

Communication functions

| Function | Connect Touch | ConnectApp Classic | ConnectApp Premium |

|---|---|---|---|

| Offline operation | ● | ● | ● |

| Cloud usage via app or tablet | – | ● | ● |

| Connection of PC/network to cloud | – | ● | ● |

| Creating saw lists from PC to cloud | – | ● | ● |

| Exchanging saw lists via cloud | – | ● | ● |

| Connection with saw optimization via cloud | – | – | ● |

| Graphical display of cutting plans / saw optimization | – | – | ● |

| Barcode scanner when retrieving saw programs | – | – | ○ |

| Label printer for saw optimization | – | – | ○ |

| Management of tool data from PC to cloud | – | ● | ● |

| Management of special tools from PC to cloud | – | – | ● |

| Management of order data from PC to cloud | – | ● | ● |

| User management | – | ○ | ● |

| Remote maintenance | – | ○ | ● |